A device fixed to the worktable of a machine and locates the work BIW Weld Fixtures Design ProcessMethodology. April 5th 8th 2022 at Capital Machines Technology Center Tampa FL.

Weld Fixture Design Page 4 Weld Fixture Specialists

In 3 is presented a study about a design of a booster for the welding ultrasonic device and is 7 approached the design and simulation of a stepped horn used in ultrasonic machining.

. Printing welding fixtures allows you to achieve the weld quality of CNC fixtures for the cost and complexity of low-fidelity solutions. That depends on how much has heshe has learnt about the BIW design process. More Older Entries.

3D Printing Welding Fixtures The only thing more critical to welding success than good fixturing is a good welder. Our CMM FaroArms utilize the most recent software to qualify directly off the 3D model for precise fast data. You will comply with design development and integration standards to improve quality and efficiency.

Welding overhead also requires you to overcome gravity. There are numerous types of welding processes based on the material to be welded. New technology helps reduce that time and the most obvious is designing fixtures in 3-D CAD software.

In this thesis welding fixture for two wheeler steering handle is modeled using CATIA software forces are calculated and an analysis has been carried out in the precisions placing of one. Why the sections of the. Welding is one of the most commonly used processes in manufacturing industry.

Sometimes two product parts can be clamped with one clamp at the same time. The analysisThe fixture design is carried out by using Solidworks modeling software and the components are analyzed by finite element method FEM using ANSYS software. When it comes to welding there are many welding fixture design considerations that you will want to take into account for fixture design service.

With any weld fixture you build in adjustability. The operations in terms of speed reliability and product output. Another view of the two-part clamp weldment.

Of software applications for manufacturers. Work directly with data flows and customer experience flows to ensure the best system possible. Weld fixtures are inspected and shimmed to nominal and inspection fixtures are typically qualified at 10 of print tolerance.

Sometimes one clamp can be used to hold parts in a fixture that runs more than one. In this thesis welding fixture for two wheeler steering handle is modeled using CATIA software forces are calculated and an analysis has been carried out in the precisions placing of one circular component over another circular component during the welding process. Whether you are doing welding on your own or you are purchasing welded products from a supplier there are many things that you need to.

Manual and Modular Fixtures. Our Focus is the research development and marketing. BIW fixture is a work-holding or support device used in the automotive industry to hold BIW parts during performing welding operation.

While the modeling of the components the material selection will be carried out. In the papers 6 and 10 are presented studies about the high. This candidate also drives product excellence by.

In Machine Tool Design Weld Fixtures and Assembly Fixtures should be designed sturdy enough to withstand being moved many times. You can choose from several clamping and locating options when you design a fixture. To order Components Call Us at 2625428891.

Leave a comment add a question sign up for future weld fixture education and updates. Welding distortion stainless steel fixture copper cooling clamping. You will also identify and correct ineffective or missing processes or tools which may be a hindrance to project execution.

Our CMM FaroArms utilize the most recent software to qualify directly off the 3D model for precise fast data. When youre finished with your fixture and need to make adjustments there are a few ways to do it. Design of Welding Fixture.

Welding Fixture Design Considerations. Allowing the clamp to sit lower in the fixture keeping it within the space parameter requirements for the weld fixture. Expertise in a surfacing software like CATIA.

Removing the dust covers from under-utilized welding robots. Download our Models that are ready for your weld fixture design. Deposition rates also are lower and its more difficult to maintain proper weld contours.

Manufacturing Engineers what standard method of 3D model component location do YOU follow to help you in the event that product changes are made. The Queen of Lean Machine Design at Rentapen gives 3 reasons why the fixture might be moved and 3 ways to design the base of the fixture to tolerate the moves. BIW Fixtures are used to securely locate position in a specific location or orientation and support the work ensuring that all parts produced using the fixture will maintain conformity and interchange ability.

Showing suppliers from Pune Filter by City. Click on the picture to watch the weld fixture design video that discusses this further using ProE Wildfire 40. Some now also are using coordinate measuring arms to speed the process.

Accessibility Repeatability Simplicity and Dependability. Weld fixture by using CAD software which is one of the software used for modeling components in most of the design based industries. AisoSoft May 21 2021 2 min read.

Weld fixtures are inspected and shimmed to nominal and inspection fixtures are typically qualified at 10 of print tolerance.

Welding Fixture Design Service By Camtek Optisolutions

How To Creat Biw Welding Fixture Design Unit G A Drawing In Fides Software Part 01 Youtube

Welding Fixture Design Service By Camtek Optisolutions

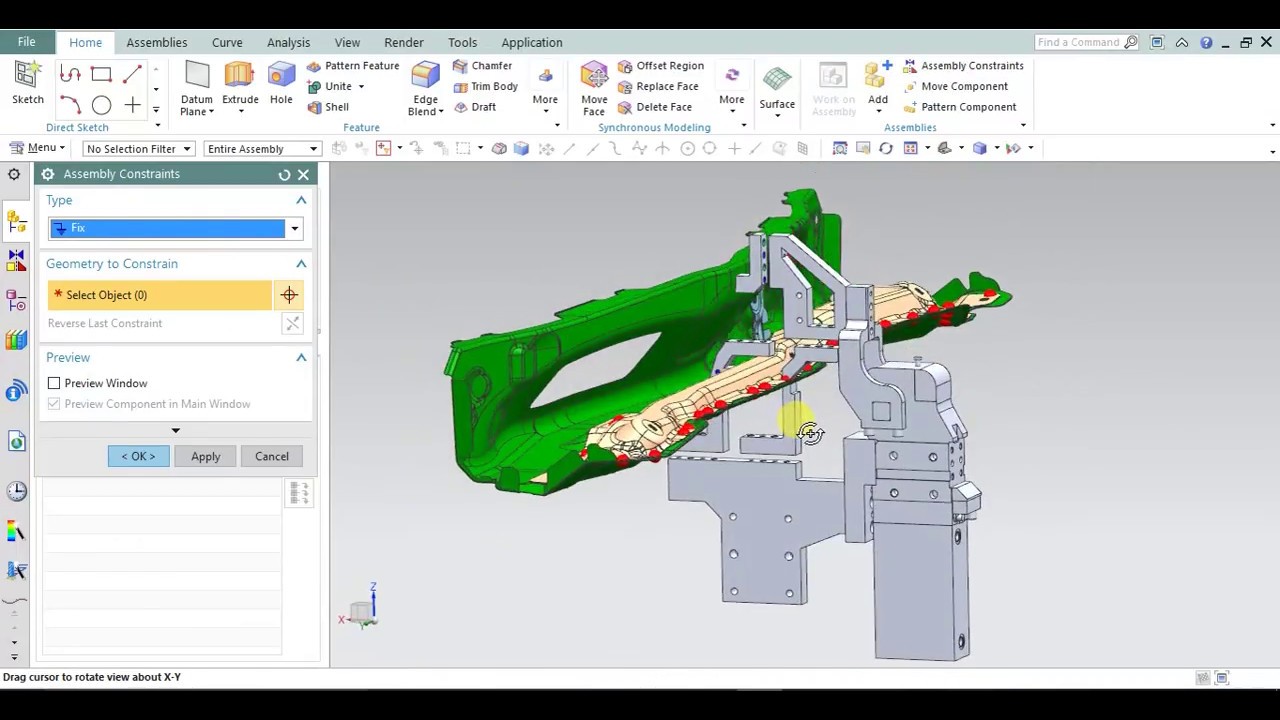

Biw Welding Fixture Design Tutorial On Ug Nx 11 Youtube

Welding Fixture Design Service By Camtek Optisolutions

0 komentar

Posting Komentar